Predictive Maintenance

An Industry leader in IoT powered goals Enterprise Asset Management

We combines the power of and deep domain expertise for quick deployment of Monitoring and Analytics. Industrial IoT and deep domain expertise for quick deployment of Monitoring and Analytics.

Improving reliability, performance, and safety are among the top priorities for industrial organizations and businesses today. They are focusing efforts and resources on controlling costs and maximizing value from existing investments. Predictive Analytics helps organizations gain the highest return on critical assets by supporting predictive maintenance (PdM) programs.

Every asset has different life expectancy & different operating environments such as Weather conditions, Types of workload, Different operating schedules & Frequency. Data is the key to insights – contains similarity in how things will behave and helps to enable operational work processes with a scalable suite of solutions to meet business objectives.

Ideally, predictive maintenance allows the maintenance frequency to be as low as possible to prevent unplanned reactive maintenance, without incurring costs associated with doing too much preventive maintenance.

Solution Overview

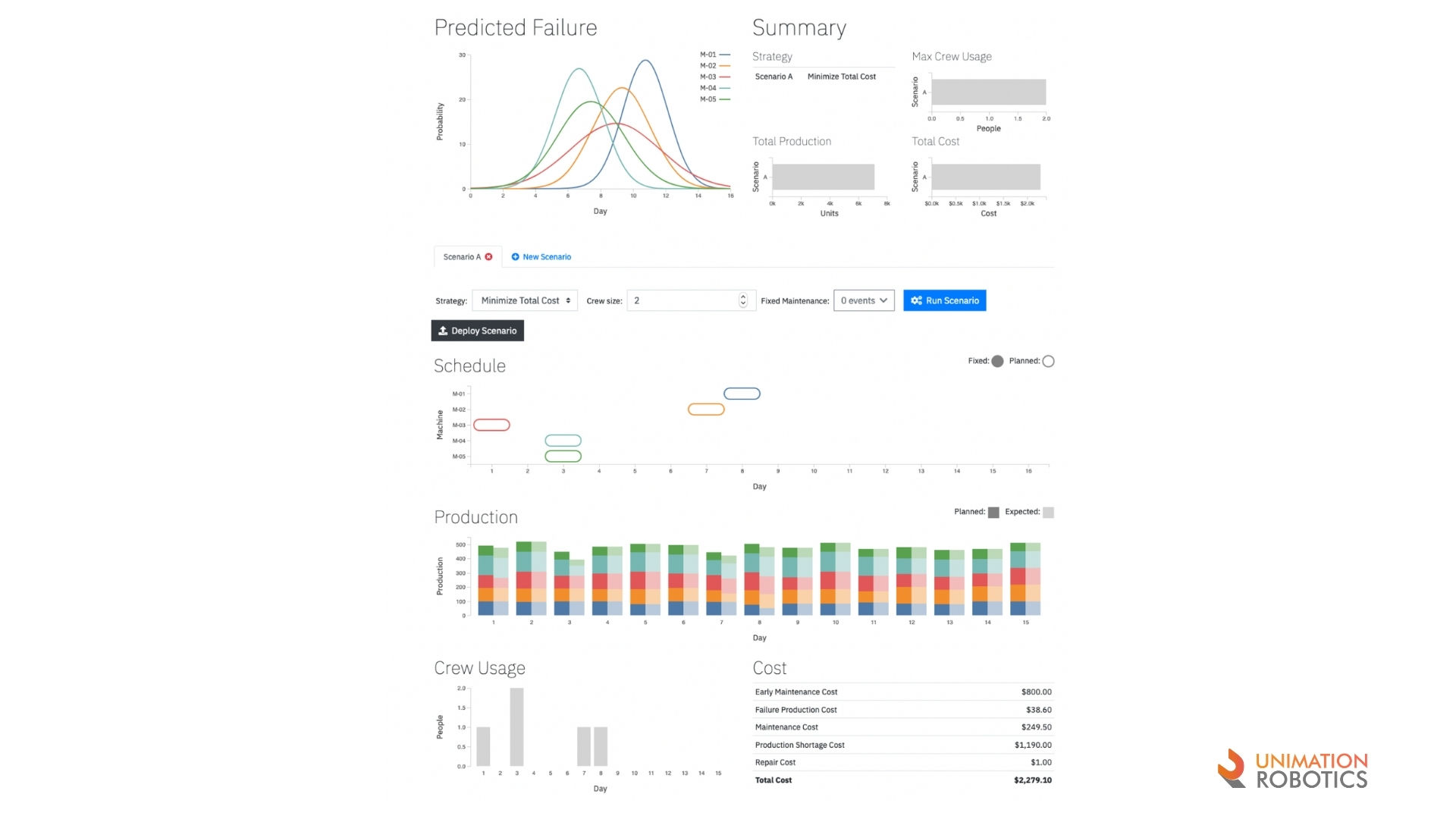

Predictive Failure

There are three main components that allow PdM to track asset condition and warn technicians about upcoming equipment failures:

1.Installed condition-monitoring sensors send real-time performance data and machine health data

2.IoT technology enables the communication between machines, software solutions, and cloud technology; essentially helping to collect and analyze huge amounts of data

3.Predictive data models are fed with all of that processed data so they can spit out failure predictions

Ideally, predictive maintenance allows the maintenance frequency to be as low as possible to prevent unplanned reactive maintenance, without incurring costs associated with doing too much preventive maintenance.

Benefits

When predictive maintenance is working effectively as a maintenance strategy, maintenance is only performed on machines when it is required. That is just before failure is likely to occur. This brings several cost savings.

- Minimizing the time the equipment is being maintained

- Minimizing the production hours lost to maintenance

- Minimizing the cost of spare parts and supplies

Predictive maintenance programs have been shown to lead to a tenfold increase in ROI & a 25%-30% reduction in maintenance costs & a 70%-75% decrease of breakdowns & a 35%-45% reduction in downtime.